Design Gallery

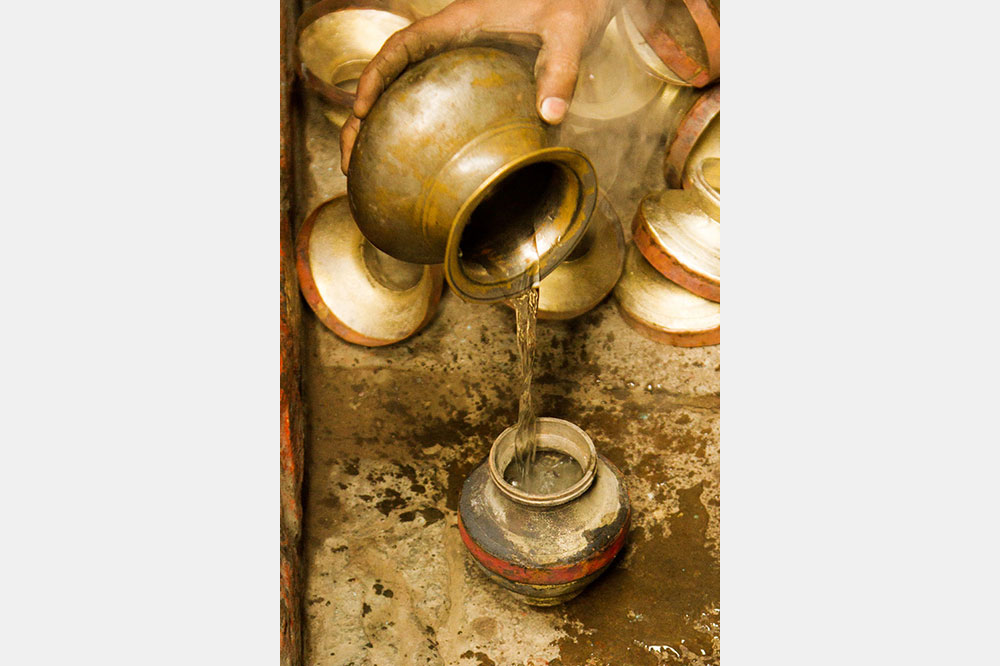

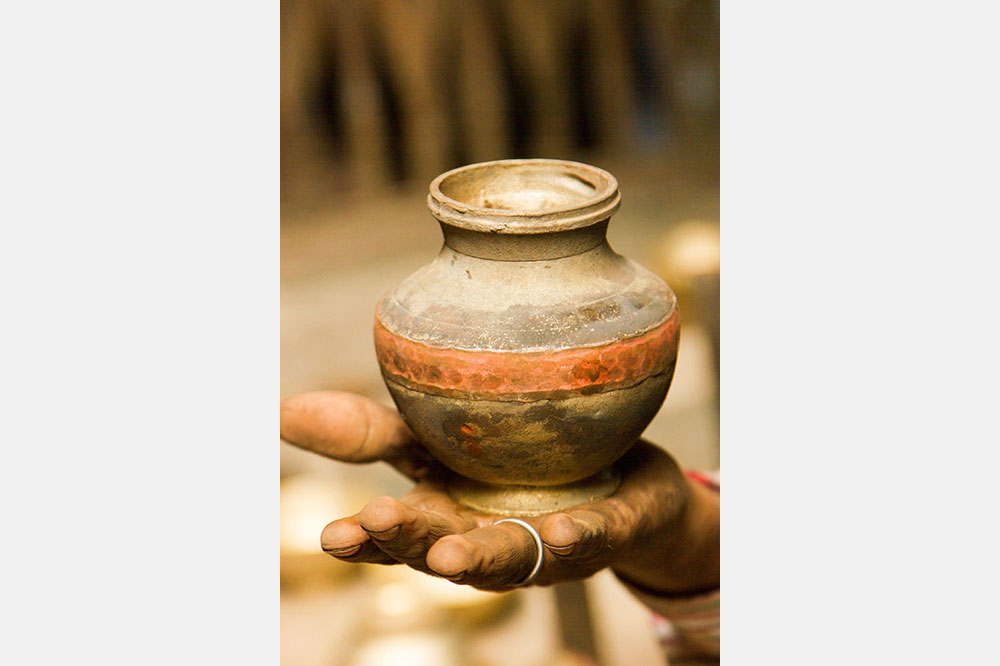

Kamandalu Making - Varanasi

Traditional Utensils of Brass, Copper and Silver

by

Kamandalu which is also known as Kamandala or Kamandalam is a traditional water pot used for carrying water by Hindu Naga sect sadhus, yogis and Buddhist monks. In Hindu mythology, it is represented that gods and sanyasis carry Kamandalu in their hands which holds a greater spiritual significance. The actual Kamandalu is traditionally made of ripe bottle gourd or the pumpkin or coconut shell or from the wood of Kamanadalataru tree (bottle gourd tree).

Nowadays Kamandalu is made of brass, copper, silver and also with clay sometimes. Aesthetically speaking it is a beautiful combination of brass and copper. As the copper represents river Jamuna and brass represents river Ganga, this type of Kamandalu is called as Ganga Jamuna Kamandalu. It is a round shaped pitcher with a wide-open neck that has a semicircular handle attached to the mouth of the Kamandalu to facilitate the grip when carried and a snout - through which the water can be poured in a controlled way.

For more details:

http://www.dsource.in/resource/traditional-utensils-varanasi