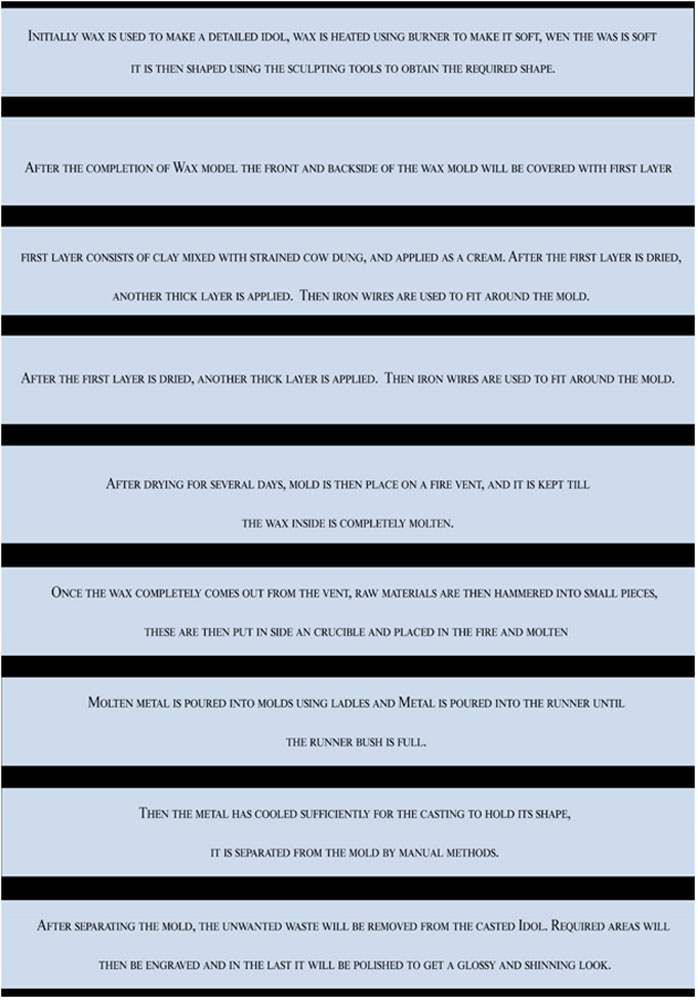

• The casting process starts by preparation of the wax model of the statue.

• The overall structure, size and figure of statue is arrived based on the Agama Shastra.

• Measurements are noted using a narrow ribbon of coconut tree leaf cut to the length of the model and folded to different lengths in proportion to the length of various parts of the model.

• Wax is a mixture of bee wax with resin and ground nut oil.

• After the wax model is dried, the fine loam or alluvial soil is applied around the model for thickness of approximately 2.5-3cms, depending on the size of the statue and allowed to dry naturally.

• Orifices are made on the mold for pouring the molten metal and draining of the molten wax and gases formed during casting.

• After drying another layer of mixture of clay and sand is applied, and naturally allowed to dry in the sun light 2-3 days.

• Once it is dried, the mold is reinforced using a metal wires in order to avoid breakage.

• The dried mold is set on fire for melting the wax inside and the molten wax is collected using a vessel, which can be reused, during this 50% of wax is lost. During earlier days the wax used was not collected and it used to evaporate as fumes and gases, so the name Lost wax method.

• Simultaneously the raw metal or alloys are weighed, according to the quantity required for casting and filled in crucibles. For bronze the ratio of copper, brass and lead are 29:2:1 Crucibles are made of special type of mud to withstand very high temperature.

• The ratio of weight of wax and alloy required to cast the product is in the ratio of 1:8 which means if the wax model weighs 1 kg then the casting will weigh around 8kg.

• Crucibles are filled with the required quantity of the metal and placed in the furnace for melting.

• Looking at the color of the flame in the fire vent craftsmen can easily identify whether the raw metal is molten are not.

• The normal flame is reddish yellow but the flame coming out from the molten metal is distinctively greenish blue in color.

• After the molten wax is completely drained, the mold is moved to a new pit which is made to accommodate the mold for casting.

• The crucible is removed from the furnace and molten metal is poured into the mold through the holes provided.

• Molten metal is poured into the mold while the mold is still hot in order to avoid sudden cooling and breakage of the casting.

• The casting is allowed to cool & set for 12-24 hours and mold is removed from the pit and casting is taken out of the mold.

• The casting obtained is unfinished and further processing is required.

• The contours and details of the original wax pattern are recaptured by smoothing the uneven surfaces and then by chiseling.

• The details of dress and ornaments as well as other final touches are engraved into the statue.

• The surface of the statue is smoothened by rubbing it with fine-grade emery paper.

• Finally, the piece is polished and packed.