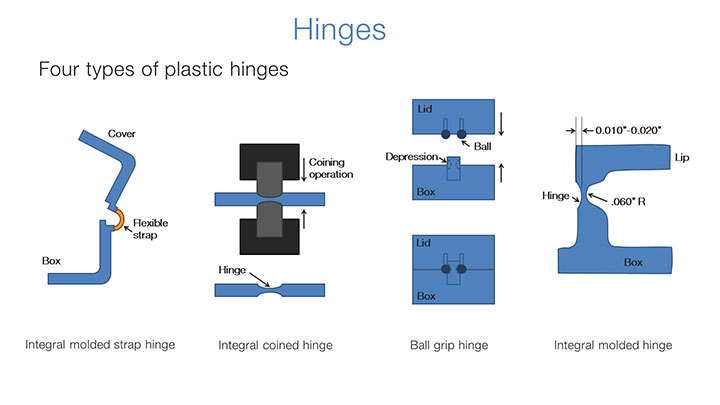

Hinges are used to join two parts in which one member is allowed to rotate with respect to other. The common application includes joining a lid to a box or joining a door to a frame. A normal assembly using hinges consist of three parts they are two parts which are to be hinged and one hinge itself. Due to certain properties of the plastics these three parts can be reduced to one in a special feature called living hinge or integral hinge or sometimes called molded-in hinge. Living hinge consist of a thin section that joins the box and a lid. It is injection molded with them in a single operation. The factors which decides the success of living hinge includes 1. The material 2. The hinge design 3. The molding conditions. Mostly thermoplastic which are flexible in thin sections are preferred for hinges. The hinge section must be thick enough to allow melt to flow through to fill downstream cavity of lid and to withstand the stresses arising during service.