When is a sheet called a sheet?

Extremely thin sheets are as small as microns are known as foils or leaves. Typically, 0.25 mm to 6 mm thick are known as sheets. When the thickness is over and above 6 mm, it is called a plate.

Sheet metal is a metal that is shaped into thin, flat pieces by hot and cold rolling industrial processes. It is one of the basic and commonly used forms of metalworking and can be processed into various shapes. Sheet metal is made out of flattening hot slabs of metal billets by way of running through a series of rollers that make them thinner and longer. The sheet is then cooled, rolled to desired thickness, and slit into sheets.

Sheet Metal Manufacturing

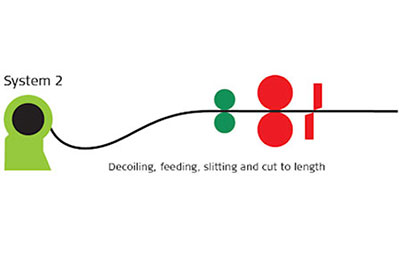

Decoiling.

Decoiling.The de-coiled and slit sheets are the basic raw material for various manufacturing processes and finishing processes before emerging as a final product.

Understanding Sheet Metal

Every professional knows sheet metal, the way it feels, the way it behaves; the only thing is the level of understanding. To beginners, it is stiff and rigid; to professionals, it is also organic in nature.

Sheet metal offers the best possible precision in the entire gamut of metal fabrication techniques. It easily surpasses hard fabrication technologies such as castings, rolled section fabrication, full welded fabrication.

The basic understanding of sheet metal – Cut and Bend

(Image Source)

The not so well understood sheet metal – Roll, Form, Press, Spin, and many other

Sheet metal is often understood at a very basic level in simple cut and bends methods; however, it also employs sophisticated techniques to bring out three-dimensional and curvy forms. Not limited to fabricating straightforward designs in industrial products, sheet metal is virtually found across all spectrums of products of everyday use such as utensils, domes, furniture structures, seats, automobiles and so, on. Besides consumer products, sheet metal is also used in shelters in the form of thin sheet structural elements.

Manufacturing Processes

There are very many manufacturing methods available to convert a sheet into a product. They vary from handcrafted products made of handheld tools to highly mechanized industrial products. It is the quality and quantities of the products to be produced that decide the manufacturing processes.

The manufacturing processes are discussed in detail in chapter 3.

Finishes

Barring pre-coated sheets, sheet metal components need to be surface finished for protection and acceptance in the market. For example:

-

Painting and Powder Coating gives appealing colours and surface finish.

-

Anodising is the process of giving a decorative and protective oxide layer to aluminium.

-

Galvanising is the process of zinc coating the steel sheets for corrosion resistance

-

Tinning is the process of tin coating making steel sheets suitable for food cans

-

Annealing is used to make metal sheets softer, thereby making them easier to bend and form

-

Tempering is used to add hardness.

-

Creation of surface textures on the surface by way of rolling add to the stiffness

The finishing processes are discussed in detail in chapter 6.

1. Types of Sheet Metal in general use

Sheets are ideal for machine fabrication, such as Punching, Bending, and Forming using the malleable and ductile characteristics of the sheet. On the other hand, plates offer much scope for very stiff and rigid product constructions such as trusses, bridges, storage tanks, etc.

The broad classification of sheet metals is

- Ferrous

- Non-Ferrous

Ferrous Sheets

- Carbon Steel

- Alloy Steel

- Stainless Steel

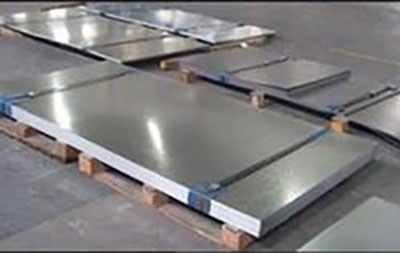

Carbon steel sheets are the ones which we come across as widely used material in the industry. They are available as ‘Hot Rolled’ and ‘Cold Rolled’ from the mill. Hot rolled products are mainly plates with thickness varying from 6 mm to upwards of 30mm. Hot-rolled sheets are also available from 2 mm to 4 mm, but they are hard and less malleable.

Hot rolled steel involves heating the steel billets at high temperatures of about 1000 deg C, which is above its re-crystallization temperature and then rolled in this hot stage to the required dimensions to form plates. Hot rolled steel sheets are hard and tough. They are generally used in the construction industry in the form of plates, angles, and channels. They are well suited for welding technology.

Cold rolled steel is essentially hot rolled steel that undergoes further processing. The hot-rolled steel is further rolled in cold reduction mills, normally at room temperature, followed by annealing. Annealing is a heat treatment process to increase ductility and reduce the hardness of the steel. It is a process where the metal is exposed to above its re-crystallization temperature but below its melting temperature for a certain period of time and cooled down. During this process, internal stresses are relieved, and a new grain structure is realized. Annealing reduces hardness and increases malleability. Because of these additional processes, cold-rolled steel is more expensive than hot-rolled steel.

Cold-rolled sheets enable good control over fabrication tolerances, concentricity, and straightness when compared to hot-rolled sheets. Cold-rolled sheets provide a superior surface finish. They have low carbon content and are softer than hot-rolled sheets.

Rust

One of the main problems in steel is that steel is susceptible to rust due to oxidation. This causes a reduction in the strength of the metal. But there are also proven solutions to prevent or minimize the damage due to rusting.

For practical purposes, Carbon Steel sheets come in the following categories

-

O- Ordinary steel (commercial quality close annealed cold rolled)

-

D – Drawn steel (drawing quality close annealed cold rolled)

-

DD – Deep Drawn steel (deep drawing close annealed cold rolled)

-

EDD – Extra Deep Drawn steel (extra deep drawing non-aging close annealed cold rolled)

Ordinary quality is for general purpose fabricated products.

Drawn quality is for close-tolerance fabricated products.

Deep Drawn quality is for stretched material products.

Extra Deep Drawn quality is for deeply stretched material products.

Typical advantages and disadvantages of steel sheets.

| Advantages | Disadvantages |

| High Strength to weight ratio | Susceptible to corrosion |

| Ductility and Malleability | Susceptible to fatigue |

| Stiffness | Susceptible to fracture |

| Suitable for all fabrication methods | Limited fire resistance |

| Allows onsite and off-site fabrication | High raw material cost |

2. HRCA Steel Sheets

Girders using HRCA Plates.

Girders using HRCA Plates.

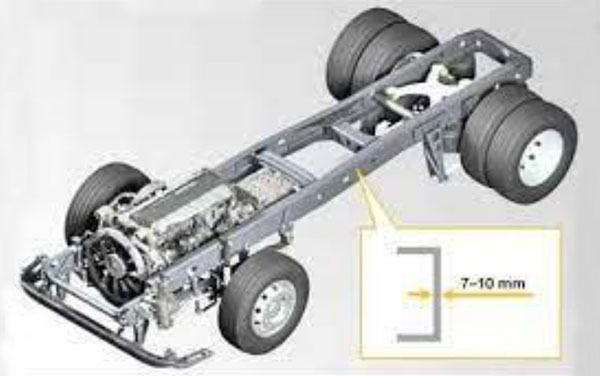

Hot rolled steel is best suited in applications where precise shapes, sizes, and tolerances are not important. Hot rolled steel sheets come with rough blue-grey surface colour and may have surface irregularities such as unevenness, roughness, and pits. The tolerance of the sheet thickness can be in the order of +/- 0.20 mm. Therefore, it requires more effort during pre-treatment before painting to obtain a smooth surface. Therefore, it is preferred to seek matt or textured surface finish during painting or powder coating partly to hide surface irregularities. HRCA sheets are advantageous where price matters more than precision. Some common uses of hot rolled steel are:

-

Structures and Constructions

-

Pipes and tubes

-

Large vehicle frames

-

Outdoor panel equipment

-

Due to advances in technology, HRCA sheets to a limited extent are made available for drawing, even extra deep drawing purposes.

| Composition of elements in HRCA sheet grades | ||||||||

| IS 1079: 2009 | Table 1 Chemical Composition (Clauses 6.1 and 6.2) |

|||||||

| SI No. | Quality | Constituent, Percent, Max | ||||||

| Designation | Old Designation |

Name | Carbon | Manganese | Phosphorus | Sulphur | Micro-Alloy | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) |

| i) | HRO | (New) | Oridinary | 0.25 | 1.70 | 0.05 | 0.045 | --- |

| ii) | HR1 | O | Commercial | 0.15 | 0.60 | 0.05 | 0.035 | --- |

| iii) | HR2 | D | Drawing | 0.10 | 0.45 | 0.040 | 0.035 | --- |

| iv) | HR3 | DD | Deep Drawing | 0.08 | 0.40 | 0.035 | 0.030 | --- |

| v) | HR4 | EDD | Extra Deep Drawing |

0.08 | 0.35 | 0.030 | 0.030 | --- |

| vi) | HR5 | (New) | Micro-alloyed Duel Phase1) |

0.16 0.16 |

1.6 2.0 |

0.020 0.05 |

0.020 0.02 |

0.20 0.15 |

(IS 1079: 2009)

| Commonly available HRCA Steel Sheets (Ex:Bokaro Steels) | ||

| WIDTH mm | TH mm | LENGTH mm |

| 900, 1000, 1250 | 2.0 | 2500,3000 |

| 1200, 1000, 1250 | 2.5 | 2500, 3000 |

| 1000 | 3.15 | 2500, 4000 |

| 1000, 1250, 1500 | 4.0 | 2500, 4000 |

| Commonly available sizes of HRCA Steel Plate Sizes | ||

| Discrete Plates | ||

| WIDTH mm | TH mm | LENGTH mm |

| 1500 To 4500 | 5.0 To 150 | UPTO 40,000 |

| 1500 To 2500 | 5.0 To 25.0 | TYP 2400 |

IS 1079– O,D,DD,EDD, typical examples being the manufacture of Chests, safes, cupboards, and other domestic and engineering items. This grade is used as a base material for general purposes and corrugated sheets, items in transportation bodies, and domestic appliances.

3. CRCA Steel Sheets

CRCA steel is an essentially hot rolled steel sheet with further processing in cold reduction mills and annealing ovens. Cold rolled steel sheets come with smooth blue-grey surface colour and will have practically no surface irregularities. The tolerance of the sheet thickness will be in the order of +/= 0.02 mm. Therefore, CRCA sheets are most widely used for the detail and definition they offer with very minimal deviation in mechanical properties. CRCAsheets are certainly the designer’s choice for appearance. The surface finish of CRCA sheets will be smooth and requires fewer efforts during pre-treatment and painting.

CRCA Sheets in Use

Over 60 percent of industrial, Commercial, and domestic products are made from cold-rolled steel.

Composition of elements in CRCA sheet grades

| SI No. | Quality | Constituent, Percent, Max | ||||

| Designation | Name | Carbon | Manganese | Sulphur | Phosphorus | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) |

| i) | CR0 | Hard | 0.25 | 1.7 | 0.045 | 0.050 |

| ii) | CR1 | Commercial | 0.15 | 0.60 | 0.040 | 0.050 |

| iii) | CR2 | Drawing | 0.12 | 0.50 | 0.035 | 0.040 |

| iv) | CR3 | Deep Drawing | 0.10 | 0.45 | 0.030 | 0.025 |

| v) | CR4 | Extra Deep Drawing Aluminium Killed (Non-ageing) |

0.08 | 0.40 | 0.030 | 0.020 |

| vi) | CR5 | Extra Deep Drawing (Stabilized Interstitial Free) |

0.06 | 0.25 | 0.020 | 0.020 |

(IS 513 2008)

The advantages of CRCA steel are:

- Precise and Accurate Dimensional Tolerances

- Good surface finish

- Improved mechanical & physical properties

- Improved draw-ability

- Good machinability

The disadvantages being:

- Less Corrosion Resistant

- Sensitive to the Moisture content

Although cold-rolled steel is more expensive than hot-rolled steel, the advantages make it useful for many applications. The finished products needless additional surface finishing to achieve a good result, as the surfaces are already smooth. Examples of cold rolled/cold drawn steel use include:

- Metal furniture

- Structural parts

- Home appliances

- Water heaters

- Metal containers

- Fan blades

- Frying pans

- Computer cabinets

Common CRCA Steel Applications

CRCA Ordinary - For basic fabrication. (Image source)

CRCA Ordinary - For basic fabrication. (Image source) CRCA Deep Drawn - For deep stretching. (Image source)

CRCA Deep Drawn - For deep stretching. (Image source)Cold Rolled Sheets are available in a wide range of strips as well as sheet forms. Different chemical compositions and modified mechanical properties are made available to suit specific Forming, Drawing applications.

| Commonly used sizes of CRCA Sheets (Bokaro Steels) | ||

| WIDTH mm | TH mm | LENGTH mm |

| 450, 600, 900, 1250 | 0.3,0.5,0.6,1.0,1.2,1.5 | 2500 |

| 900, 1000, 1250 | 1.2,2.5,3.15 | 2500,3000 |

4. Rust protected Sheets

There are variations of sheets available with rust protective coatings.

Some of them are:

- Galvanized sheets

- Pre-coated sheets

- Plated sheets

- Speciality coated sheets

Galvanized Steel Sheets

There are two kinds of spangles for hot-dipped galvanized steels, one is regular spangles, and another is zero spangles.

The regular spangle is where the zinc layer coated is condensed under normal conditions after galvanizing, which is mainly used for general purposes. These are mainly used in building roofing and on applications occasion where there is less human direct contact.

Zero spangles are where the steel sheet has a very fine surface appearance after zinc coating, which has been applied through a special process. These sheets are used mainly in electronic equipment chassis and other such sensitive applications.

Galvalume Steel Sheets

Galvalume sheets are steel sheets that undergo the process of hot-dip of aluminium-zinc-silicon alloy coating. It differs from galvanized sheets because galvanizing is one hundred percent zinc coating, while galvanizing comprises 55% aluminium, 43.5% zinc, and 1.5% silicon. Over time galvalume tends to perform better than galvanizing.

Advantages of Galvalume Sheets

- Heat resistance - Withstands over 300 deg C.

- Thermal reflectivity – Thermal reflection is double as high as galvanized sheets.

- Corrosion resistance – High corrosion resistance due to high aluminium composition.

- Economy For a given weight of coating layer, galvalume offers triple the size of galvanized sheet.

Pre-Coated Steel Sheets

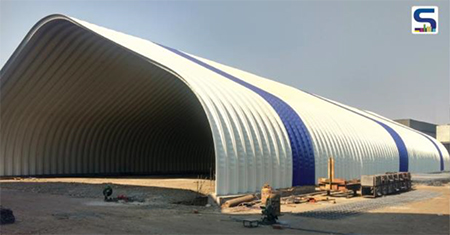

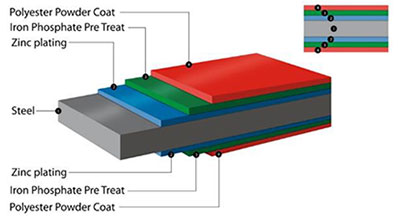

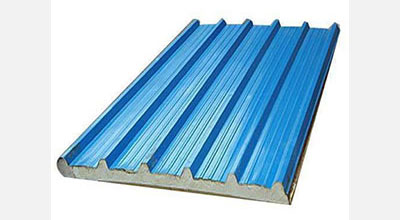

CRCA sheets in thickness of 0.35 to 0. 55 mm are available in the pre-coated form. They are mainly used as roofing sheets and, to some extent, as cladding material. A pre-coated CRCA sheet is first given a zinc coating followed by a primer coat and a final surface coat. The pre-coated sheets are also available with integrated polyurethane foam as protection against heat. Pre Coated sheets are extensively used as roofing and in Pre Engineering Buildings (PEB).

Typical application of pre coated sheets in Pre-Engineered Buildings (PEB). (Image source)

Typical application of pre coated sheets in Pre-Engineered Buildings (PEB). (Image source) Typical application of pre coated sheets in Pre-Engineered Buildings (PEB). (Image source)

Typical application of pre coated sheets in Pre-Engineered Buildings (PEB). (Image source)Truss less Roofing

The strength of the steel sheet is such that it need not always have an engineered truss to support a roofing sheet in pre-engineered buildings. In a classic example, the physical properties of corrugated sheets are adequate to self-support it on the roof. The corrugations of the sheet act as ribs to strengthen the sheet. Corrugated sheets are rolled into curved shapes and fitted onto buildings. Truss less roofing is increasingly becoming popular where roof spans are not large.

Truss less Roof (Image Source)

Billets.

Billets. Flats.

Flats. Hot Rolling.

Hot Rolling. Coiling.

Coiling. Slit Sheets.

Slit Sheets. (

(

Researchgate.net

Researchgate.net Freepic.

Freepic. Vehicle Frames.

Vehicle Frames. HRCA Outdoor Electric Panel Box.

HRCA Outdoor Electric Panel Box. HRCA Kiosk Panelling.

HRCA Kiosk Panelling. Automobile.

Automobile. Machine Body.

Machine Body. Equipment Housing.

Equipment Housing. Shelving.

Shelving. Home Furniture.

Home Furniture. Chair Seating.

Chair Seating. Utensils.

Utensils. Men’s Ware.

Men’s Ware. Construction.

Construction. CRCA Drawn - For quality finish.

CRCA Drawn - For quality finish. Reular Spangle Sheets.

Reular Spangle Sheets. Zero Spangled Sheets.

Zero Spangled Sheets. Colour coated sheet rolls.

Colour coated sheet rolls. Colour coated sheets as Roofing material.

Colour coated sheets as Roofing material. Pre Coated CRCA Sheet.

Pre Coated CRCA Sheet. Pre Coated CRCA Sheet with integrated PU Foam.

Pre Coated CRCA Sheet with integrated PU Foam.