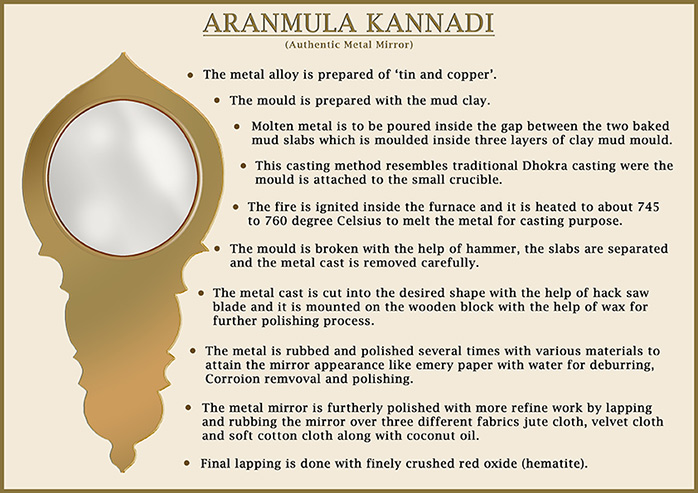

The making of this mirror embeds multiple processes that require lots of patience and persistence. Firstly the metal alloy is prepared of ‘tin and copper’ and tested for the proper proportion and quality. This metal alloy is a binary copper-tin alloy with 30 -34% of tin, this proportion is closely related to a bronze metal alloy. Later it is broken into small chunks for casting. The mould is prepared with the mud clay from the nearby paddy fields by powdering and refining them. The clay is mixed in proper consistency in order to make two flat surfaces like slabs. Later the slabs are dried under the sun and baked to make them hard. Once the baked mud slabs are ready the coal is applied by rubbing it over its one side surface with water to give it a smooth finish. Two baked mud slabs are covered with a coat of coal on the surface of either side of them. The slabs are placed one onto one, and the coal coated are facing each other. A gap will be made between two slabs with a small piece of wax protruding outside the mould to make an opening for pouring metal and small alloy pieces in order to acquire the required thickness. The baked slabs are packed with the mud clay mixture completely around them which holds the slabs together and seals the openings. The slabs are packed with two to three layers of the clay mixture and small clamps are stuck on three sides of the mould to make the mould strong except for the wax side. The place of the wax is noticed and a cup out of clay is stuck onto the mould and two holes are made inside the cup one on the wax, the other towards the side of the cup for airflow vent. The mould is kept dry under the sun for a day and it is then dusted from the inside of the cup to make the casting easy. The mould looks similar to one of those desert water canteen or a hot water bag. The cup is filled with the metal alloy chunks completely and a wet paper or cloth is covered over the cup in order to avoid dust particles mixing with metal. The clay mixture is packed over the cup and left for drying under the sun. The cup enacts like the crucible. Once the complete mould is dried the casting process begins. The furnace is kept ready for melting the metal by placing the moulds filled with metal inside the furnace, the cup side is downward and the slabs' side is upward. Multiple moulds are placed inside to align with each other and coal is filled to the half upon which the coconut coir is put. The fire is ignited and it is heated to about 745 to 760 degrees Celsius.

The metal inside would have melted and is ready for casting. There are two processes happening at the same time one is melting the metal other one is preheating the mould before casting. Once the required heat is obtained the mould is picked up by the lifting tongs carefully and tilted carefully upside down, so that the molten metal is poured into the mould from the opposite side of the air vent hole. The mould is kept in a place to cool down the temperature. The clay cup and the sealing are broken with the help of a hammer. The slabs are separated and the metal cast is removed carefully. The metal cast is dusted tenderly and consciously. The metal cast is cut into the desired size with the help of a hack saw blade and ruler. After cutting the edges of the metal mirror plate to the required size and form the metal is stuck on a thick rectangular wooden polishing block along with a rear handle with natural adhesive beeswax. The thick rectangular wooden polishing block is made according to the size of the mirrors. The block is embossed by half a centimeter in the middle in a circular form. The wax is placed on the top of the embossed wooden block and a knife is heated to settle the wax flat. After the application of wax, the metal is preheated with very little heat and mounted on the wax. Later on, the metal mounted on the block is let to cool down, wax turns harder after the cool down and creates a strong bond between the block and metal. The metal is rubbed and lapped up to a certain time with the consciousness of heat produced by giving gaps between the rubbing processes, letting the metal cool down at regular intervals. The metal has to be at room temperature because the sustainability of heat is less. Thus the artisan keeps three to five mirrors for polishing where each one is rubbed alternatively once its surface turns cool. The metal is then rubbed and polished several times with various materials to attain the mirror appearance. Firstly the metal is scrubbed thoroughly with emery paper and water for debarring, corrosion removal and polishing. The grades of the emery paper reduce gradually when the mirror attains smoothness. After the repetitive process of emery paper lapping for two days. The metal mirror would have acquired a bit of lustrousness and reflectivity. Then the metal mirror is given to the master artisan for more refined work and polishing. The master artisan rubs the metal mirror on three different cloth materials to acquire a high-quality reflective surface. The jute cloth, velvet cloth and soft cotton cloth are used in the process of polishing. Firstly the mirror is oiled on top, with coconut oil and rubbed over the soft jute cloth, then it is oiled again and rubbed over the velvet cloth finally it is oiled and rubbed over the soft cotton cloth. Final lapping is done with finely crushed red oxide (hematite). Red oxide is also used in cleaning the mirror when it tarnishes. After several turns of the lapping process, the metal mirror acquires the characteristics of the mirror. The mirror is then detached from the block by melting the wax. The mirror is then fitted to the frame accordingly with the support of the wax or the brass ring. To avoid the tarnishing of the mirror, it has to be polished with red oxide or vermilion occasionally and to eradicate the grease on the mirror the solidified coconut oil has to be rubbed over. The mirror is supposed to be polished in a vertical motion.

The brass mirror frame is made through the box casting process. The frames are made in very interesting different themes and designs. The designs depend on the customary willingness. Firstly the frame is made in wax or a thick maida paste. The article made is dried and kept. The box moulds are taken and a fine clay mud mixture is made, then filled onto the first box tightly. Later the article made is taken and placed in the right place as well as pressed tightly so that half of the article’s impression is acquired. The box frame is placed on the top and chalk powder is slightly spread along with the frame in order to bifurcate easily the layers while removing. Later on, the clay mud mixture is taken and filled completely up to the end of the second box frame and pressed with a wooden plank. After a certain time, the upper box frame is removed carefully and the impressions are attested. Later the second box frame is taken out and the metal frame article is removed. The artisan attests to the impressions on both the box frames obtained and digs two channels connecting the impression. The channels are made to pour the liquid metal and release the air out. Further, the mould box is put together like previously and join it with the clay around the frames to ensure they are leakproof. In a coal furnace, coal is been burnt to obtain a high amount of heat which helps in melting the brass metal in crucible. With the help of Gas propane and a torch, the furnace is ignited. The artisan ensures that the metal is pure by removing the dust particles with the help of the rake. Once the metal is melted, the artisan picks up the Crucible with the help of the furnace lifting tongs. With the help of the other tongs, the crucible is slanted towards a channel hole to pour the liquid metal into the box mould. Once the metal flows out from the other channel hole (also called a gate) the artisan stops pouring the metal. After a while artisan ensures with the casted metal, to check with the obtained solidness. Both the box frames are released from the cast. The cast is cooled down by putting it in the water. Artisan removes the channels in the cast by hammering it. The cast is dusted, filled, buffed and final shaping is given by the skilled artisan with various Chisel tools. The cast is washed with dilute nitric acid to get bronze glaze on the frame, which later is washed in tamarind pulp to give a lustrous look and brushed with clean water to get the shinning brass frame.

Flow Chart: